Bench Grinder Sharpening

Next dress the bench grinder wheels regularly to remove clogged grains.

Bench grinder sharpening. It needs to be well balanced. Clean the blade using a wire brush and wipe the surface using an oily rag to remove rust and dirt. Sharpening is easy if you don t try to do it on the cheap.

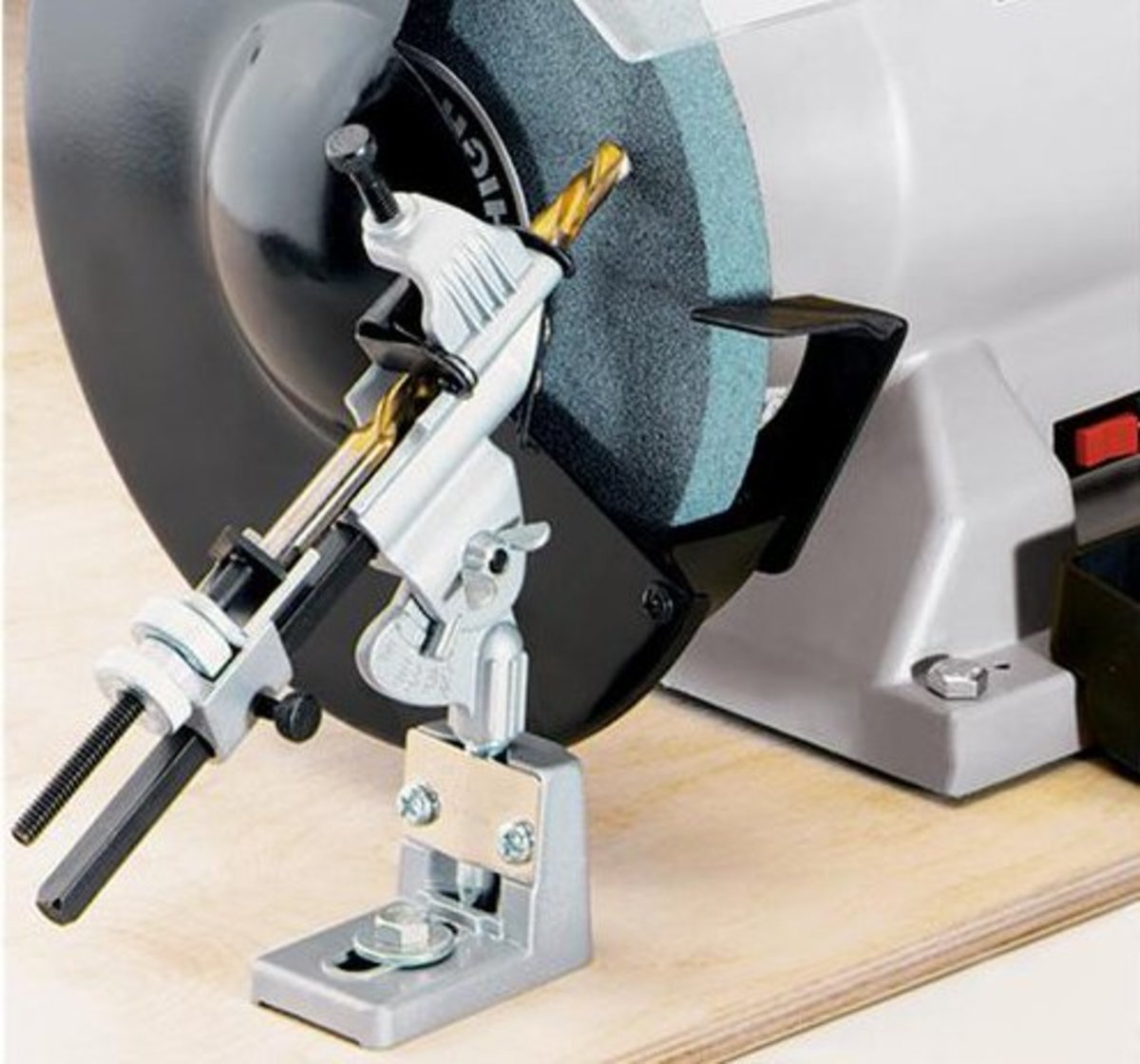

When you are looking for a good bench grinder to handle your lawnmower blade sharpening here are some things to look for. With an eight inch wheel and the proper wheels along with a good jig you will pick it up quickly. There are a lot of them on the market for around a hundred dollars.

But for sharpening a low speed grinder running at 1 750 rpm is a better choice. For the ones that seem lightly damaged first try reconditioning their cutting edges with a mill file and sharpening stones. Turn the bench grinder.

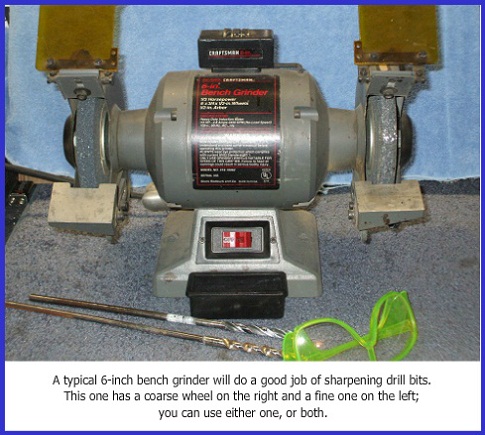

Inspect the knife to find out the number of blades it has. The lower speed reduces the chance you ll overheat the edge of your tool. If the damage is too extensive use a bench grinder with a 6 inch or.

Unless they re variable speed most bench grinders run at about 3 450 rpm. This lets you know that there. First use aluminum oxide bench grinder wheels for ferrous metals and silicon carbide for all the others brass copper aluminum.

You want an 8 inch wheel and not a 6 inch one. A heavy duty grinder is preferred. Shop water cooled grinders slow speed grinder and more at woodcraft.

If you re careful and keep the wheel dressed more on that in another tip these high speed grinders work fine. Put the tools in your oven not too hot just set your oven to 350 degrees and let the tools sit. Keep tools sharp and safe by using a bench grinder.

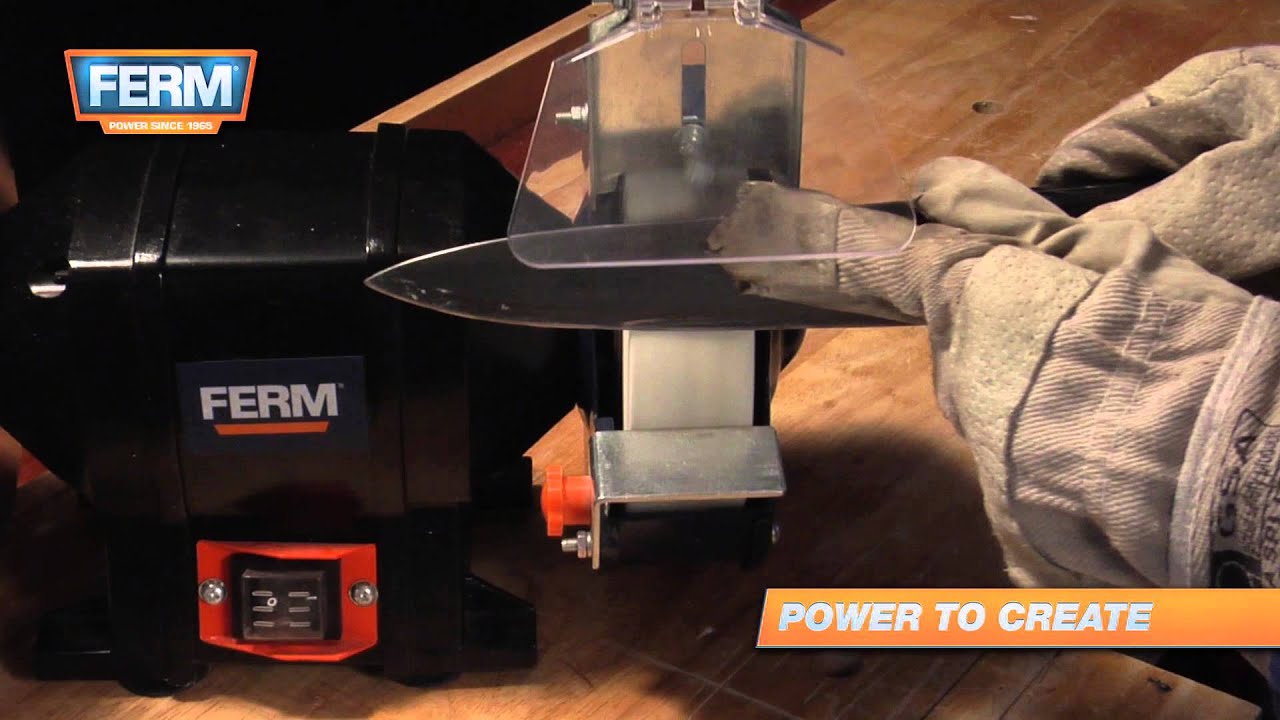

Here are some tips to help you sharpen your old tools on a bench grinder. Procedure clean the knife. Angle grinders are versatile handheld power tools perfect for grinding cutting and polishing.

Pruning knives for example. The quieter the motor the better. Match the wheel to the metal being sharpened it is the right tool for the job rule that always applies.